What is trim loss?

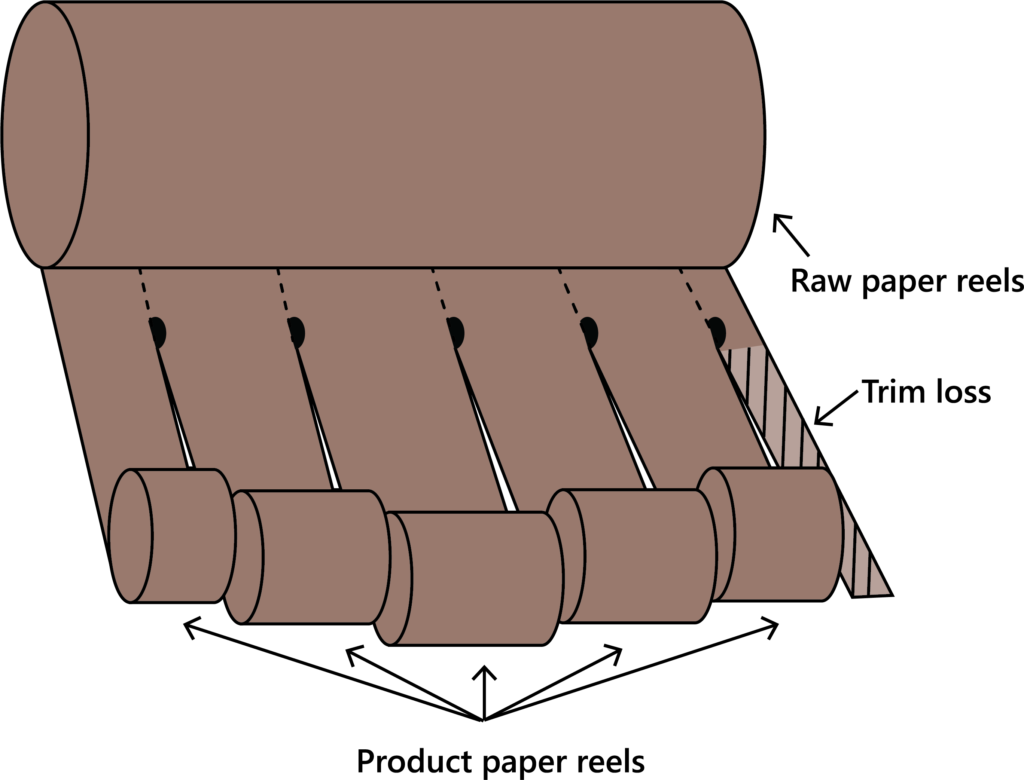

Paper converting process where master rolls are transformed to paper sheets with minimal paper loss, including trim loss, set up the loss, and over-make loss.

The trim loss appears when an order specified by a customer is to be satisfied by cutting out a set of product reels from a wider raw paper reel. It also occurs when the paper roll edge is damaged during transportation or storage.

Reducing waste is always the client’s priority topic. When “waste” happens to be the material and product, it is as much a matter of real dollars to you as it is “waste” and trim loss to our customer.

So people try their best to optimize the trim loss. But when the trim loss is reduced, the trimmed edge width becomes more and more narrow. Then the trimmed strip will easily tear down when blowing by the air fan through the pipe.

What’s the reasonable trim loss width?

For the slitting and rewinding machine, usually, the waste slit width is 8-20mm. If it is too narrow, it will be easy to tear down. If it is too broad, it will get stuck in the air tube.

It depends on the paper type. If the paper is very thick, it better reduces the trim loss width. Anyway, when the paper thickness is very thin and the stretch degree is very low. The trim edge width could increase a little. Typically more than 10mm.

What to do if raw material roll width is fixed?

One of our clients buy a 900 model thermal paper slitting machine, and it takes 16 slit blades to get 15pcs rolls each time. But to save the budget, they bought an 851mm raw paper jumbo roll. That means the trim waste width has to be 5mm in total. That is 3mm on the left and 2mm on the right. It causes a lot of headaches for the operator.

How to solve it under such a challenging situation?

1. Check the upper slit blade cut edge. Is there any notch on it? If yes, it means the blade needs to be changed to the new one.

2. Check the paper reel’s two ends if it is damaged during transportation. If the surface is damaged, check the damaged depth, and increase the waste trim width accordingly.

3. Try to stop the web guiding system from working. For example, it is incredibly narrow if the total trim width is only 1mm or 2mm. Any tiny power that has been done during the traction process, the strip will break down.

4. Check the power of the air fan or suction fan. Try to reduce the air volume. Then the blowout air power will be small.

Small knoledge for waste edge collection way

1. Centrifugal fan suction type

2. high-pressure blower type

3. Trim loss rewinder

That’s all for today’s sharing. If you have a different idea, please feel free to leave a message or email us.