Top 4 problems during running thin food wrapping paper sheeter, wrinkle/curl/static/break…

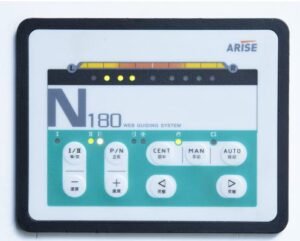

Buttons on control panel Operation process Inspection steps: Remark: machine operation side we mentioned above is the touch screen located side. The sensitive degree increases

What’s the reasonable trim loss width?

For the slitting and rewinding machine, usually, the waste slit width is 8-20mm. If it is too narrow, it will be easy to tear down. If it is too broad, it will get stuck in the air tube.

It depends on the paper type. If the paper is very thick, it better reduces the trim loss width. Anyway, when the paper thickness is very thin and the stretch degree is very low. The trim edge width could increase a little. Typically more than 10mm.

For web guiding system, most often used is unwind guide. Let’s learn more about this system.

Put a wooden stick under the lower arm.

Then press the “down” button on the control panel. Keep pushing until the upper arm chuck height is the same as the lower one. Then stop.

Use a wrench to fix the screws on the arm surface.

Lock the screws on the back side of the arm.

Follow the above tips, and you will solve the problem perfectly. It is just one step of machine adjustment.

The base material in the video we call is a flexible magnet. The surface layer is photographic paper. The two types of material laminated together then become a new popular product-magnetic photographic paper.

There is static after a prolonged storage time when sheeting plastic film, PVC/PP/PET laminated material, and foil laminated material. It causes the material feeding problem during

All basic questions and answers of our business tips are here. Take a look right now.