When we ship the machine, the client always asked us to stick a shipping mark onto the wooden case. Some people use copy A4 paper to print, some people use adhesive paper to print. When we buy some new goods, there is a sticker on the outside of the package box. Even buy a new tire for our car, there is a paper sticker on it. Wow, there seem so many paper stickers in our daily life packaging. Today we are going to talk about the “paper sticker” and the cutting machine that possibly working with it.

What is Adhesive Paper?

Self-adhesive paper is a kind of paper that is made of paper, film, or special materials, coated with adhesive on the back, and coated with silicon protective paper as the base paper.

The Structure of the Self-adhesive Paper

* Top coating- face coating, generally used to improve printing performance.

* Facestock- surface materials (comprehensive selection according to customer requirements, actual stickers, and use environment).

* Primer-back coating is usually used to improve the adhesion between the glue and the back of the surface material.

* Adhesive- glue (usually used in durable goods such as electronic products, cars, tools, etc., which have high adhesion and weather resistance; hot melt glue has a high viscosity, low price, wide use, but poor weather resistance and heat resistance; water glue is environmentally friendly, good processability, usually used in food, medicine, daily chemical, etc.).

* Release coating- release coating, composed of silicone oil (water separation and UV curing, Dow corning is the largest supplier), reduces the stickiness between the glue and the base paper, and enables the glue to be stripped from the base paper when labeling.

* Release liner- release layer, mainly made of transparent PET film or paper (transparent Gracindi paper, opaque yellow base paper, CCK (coated clay paper, etc.). Only transparent base paper can be used for automatic labeling.

* ABC Coating- is mainly used to prevent the glue from penetrating the white surface of the base paper and to avoid adhesion between the back of the base paper and the surface material when the label is rolled up into a large roll.

Standard Size of Adhesive Paper

1. The size of common self-adhesive label paper is 199.1mmx288mm, 210mmx297mm, and the weight is about 8.0g-9.2g. The scope of use includes manual label paper, advertising label paper, shipping label paper, and so on.

The scope of use of label paper with specifications 60 to 40 includes logistics management label paper, outer box packaging label paper, different specifications of bobbin paper, roll core size: generally 40mm.

The specifications of other self-adhesive labels: 85x 50, 80x 100, 65×120, 60×35, 55×30, 50×165, 52x 52, 45x 25 and other custom sizes.

2. Paperweight requirements: not less than 185g/m ², the thickness of not less than 18 filaments.

3. Paper substrate requirements: tissue paper for 80g/m ²high-density copper plate, thickness not less than 8 wire; base paper for white background (including coating film) ratio lower than 85g/m ², thickness not less than 10 wire; coating glue for hot melt glue.

4.Paper appearance requirements: flat, whiteness standard, no rotten paper, no overflow paper, no bevel, full-page quantitative 5000 sheets, height not less than 90 cm. Paper technical standard: the ring initial adhesion is not less than 12N, the stickiness is more than 20 hours, and the glue content is not less than 20g/m ²

Self-adhesive Paper Printing

The so-called self-adhesive printing is the process of transferring ink and other substances through the printing plate to the surface of the printing material pre-coated on the back under certain pressure. Compared with ordinary printing, self-adhesive has the following characteristics:

1. The investment is small, the effect is quick. Most of the self-adhesive printing materials are trademarks and stickers, which have the advantages of small format, fast printing speed, and less waste.

2. The printing method is flexible. Self-adhesive is not limited by the printing method, traditional printing plants can use offset press or screen-printing machines for printing. 3. With many functions, self-adhesive is widely used in food, cosmetic goods and bar codes, etc., and can also be used as signs in special environments such as electronic products and mechanical products.

The Types and Uses of Common Self-adhesive Paper Labels:

1. Calendering writing paper, offset paper labels, material: multi-purpose label paper, uses: for information labels, bar code printing labels, especially suitable for high-speed laser printing, but also suitable for inkjet printing.

2. Coated paper self-adhesive label, material: multi-color product label general label paper, use: suitable for medicine, food, edible oil, wine, beverage, electrical appliances, cultural goods information label.

3. Mirror coated paper self-adhesive label, material: high-gloss label paper for advanced multi-color product labels, uses: suitable for information labels of drugs, food, edible oil, wine, beverages, electrical appliances, and cultural goods.

4. Aluminum foil self-adhesive label, material: general label paper for multi-color product label, use: high-grade information label suitable for medicine, food, and cultural goods.

5. Laser film self-adhesive label, material: general label paper for multi-color product label, use: high-grade information label suitable for cultural goods and decorations.

6. Fragile paper self-adhesive label, material: after peeling off the self-adhesive seal, the label paper is broken and can not be reused. Use: for electrical appliances, mobile phones, pharmaceuticals, food, and other anti-counterfeiting seals.

7. Thermal paper self-adhesive labels, uses: suitable for price tags and other retail uses and other information labels.

8. Self-adhesive label for heat transfer paper, application: suitable for printing labels in microwave ovens, weighing machines, and computer printers.

9. Removable adhesive label, material: surface material has coated paper, mirror-coated paper, PE (polyethylene), PP (polypropylene), PET (polypropylene), and other materials, uses: especially suitable for tableware, household appliances, fruits, and other information labels. After peeling off the self-adhesive label, the product does not leave a trace.

10. Washable adhesive label, material: surface material has coated paper, mirror-coated paper, PE (polyethylene), PP (polypropylene), PET (polypropylene), and other materials, uses: especially suitable for beer labels, tableware, fruits, and other information labels. After washing with water, the product does not leave traces of self-adhesive.

11.PE (polyethylene) self-adhesive label, material: fabric has transparent, bright milky white, matte milky white, water, oil and chemical resistance, and other important properties of the product label, use: for toilet products, cosmetics and other extruded packaging, information label.

12.PP (polypropylene) self-adhesive label, material: fabric has transparent, bright milky white, matte milky white, water, oil and chemical resistance and other more important product labels, uses: for toilet products and cosmetics, suitable for heat transfer printing information label.

13.PET (polypropylene) self-adhesive label, material: fabrics are transparent, bright gold, bright silver, sub-gold, sub-silver, milky white, matte milky white, water, oil and chemical resistance and other more important product labels, use: for toilet products, cosmetics, electrical appliances, mechanical products, especially suitable for information labels resistant to high-tech products.

14.PVC self-adhesive label, material: fabric has transparent, bright milky white, matte milky white, water, oil and chemical resistance and other more important product labels, uses: for toilet products, cosmetics, electrical products, especially suitable for high-tech products information label.

15.PVC shrink film self-adhesive label, use: suitable for battery trademark special label.

16. Chemical synthetic paper, material: anti-water, oil and chemicals and other important performance of the product label, use: for high-grade products, environmental protection products information label.

Application of Self-adhesive Tape:

1. Packaging industry: shipping marks, postal parcels, letter packaging, transport goods marking, envelope address labels.

2. Commodity industry: price tags, product description labels, shelf labels, bar code labels, drug labels.

3. Chemical industry: marking of paint materials, packaging of gasoline engine oil products, and various special solvent products.

4. Electronic and electrical appliance labels used in the electronic and electrical industry: there are many durable self-adhesive labels on all kinds of electrical appliances, which have a large unit area and a large number of labels. In addition, self-adhesive labels are also widely used as a description of industrial products (computers, etc.), which also drives the demand for self-adhesive labels.

5. Logistics labels in the logistics industry: in recent years, the logistics industry is rising in China, and there is an increasing demand for variable information printing labels in modern logistics, such as storage and transportation labels, baggage labels, supermarket labels, and so on.

6. Pharmaceutical labels used in the pharmaceutical industry: self-adhesive labels have been increasingly used in drug packaging. with the over-the-counter sale of over-the-counter drugs, drug manufacturers and consumers pay more attention to drug packaging. to a large extent, this will prompt drug manufacturers to accelerate the transformation from traditional labels to self-adhesive labels.

7. Self-adhesive sticker is a kind of multi-way advertising material widely used in the advertising industry, which is best matched with an instant engraving machine. The engraved products are widely used in a lightbox, signboard production (laminating), car body advertising production, permanent signs, signs, computer cutting patterns, window patterns, display board production, and so on.

The product back adhesive is acrylic solvent-based pressure-sensitive adhesive, excellent adhesion, polymer Calendering polyethylene base rubber, with the characteristics of multi-color, strong color retention and uniform color, good weather resistance, pollution resistance, and good shrinkage resistance. it has a service life of more than three years, and it is a cost-effective method for ordinary facade decoration. Other industries: anti-counterfeiting tags, encrypted tags, anti-theft tags.

The Adhesive Paper Market Price in China

The price is measure by square meter or roll. Below pictures are the price for B2B platform for reference:

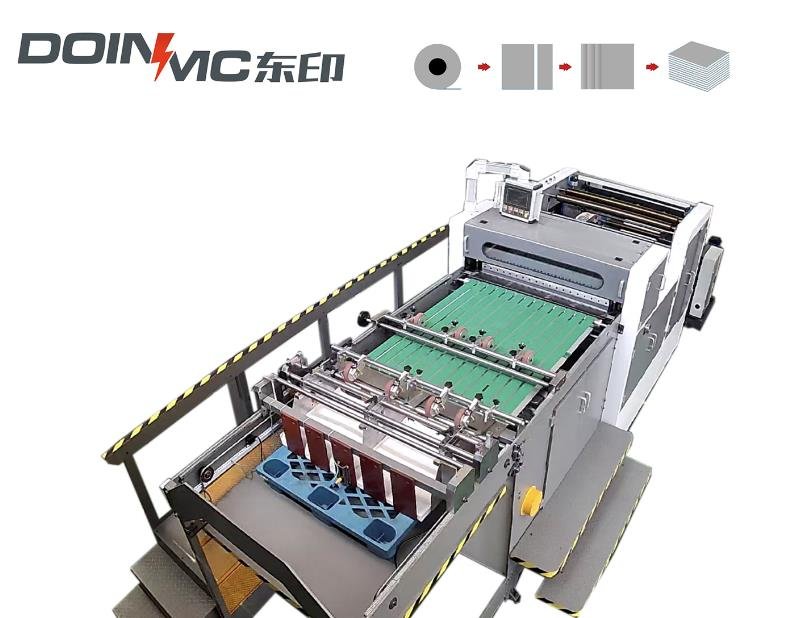

Adhesive Paper Roll Cross-cutting Machine

Working Theory

1.The main contents are as follows: 1. The paper slitting machine should cut the whole roll or the whole raw material with a fixed length, and use the fixed-length slitting control.

2. The slitting length can be set continuously. If there is an error in the actual slitting length, it is easy to be calibrated by setting parameters.

3. The slitting control of the paper slitter is divided into static and dynamic slitting: accurately stop the machine when the set length reaches, then static slitting processing, and restart the operation after slitting; when the set length arrives, the paper slitting machine sends out slitting signal without stopping, and the slitting machine cuts dynamically in the process of material movement.

Attention Points in the Operation of Self-adhesive Paper Cutting Machine

1. Before use, the machine should check whether the working position is properly adjusted, the lubricating parts that need to be lubricated should be filled with lubricating grease in advance, and at the same time should insist on whether the cutting tool on the tape slitting machine is sharp.

2. Before working, we should also check whether the machine is abnormal and enter the order for processing into the computer for inspection in advance.

3. Before the self-adhesive paper slitting machine is turned on, the operator should ensure that there is no other personnel around it, to avoid accidental injury to other personnel.

4. Ensure the normal voltage, current, and hydraulic pressure before starting up, to ensure the safe and effective operation of the equipment.

5. During the operation of the self-adhesive paper slitting machine, to avoid involving the hand in causing personal injury, we should pay attention not to touch the film roll or roll core in operation.

6. When operating the self-adhesive paper slitting machine, you should be careful not to use knives or hard objects to scratch or cut each roll core.

7. After the self-adhesive paper slitting machine is put into work, the best working state of the equipment should be adjusted in time according to the production situation to ensure that the indentation of the cutting machine is moderate, the cutting is burr-free, and the trimming position on both sides is suitable.

8. The equipment should be cleaned and maintained regularly when it is not in use to ensure that it can be used directly next time. For example, it is necessary to inject butter every half a year when the transmission chain and gears are short of oil; the lubrication of the reducer, the lubrication of the bushing and the shaft on the coiling shaft, the lubrication of the gas source processor, or regularly check whether the screws are loose or not, it should be noted that the belt slitter should not use corrosive chemicals to wipe the embossed wheel, rubber wheel, and coiler during maintenance.

Customized Adhesive Paper Roll Sheeter For Spain Client

- Waste edge rewinding device

2. Crush blade slitting which means less glue stay on blade after hours of working

And other anti-sticky treatment

Other Related Adhesive Paper Processing Machine

Adhesive paper coating machine

Printing Machine

Slitting and rewinding machine

Die-cutting machine

To open a adhesive paper processing factory, coating machine, slitting and rewinding machine, automatic sheeting machine are the most basic needs.

Adhesive Paper Manufacturer Visiting in China

In order to develop a more suitable adhesive paper sheeting machine, we DOINMC visited clients near Wenzhou city. And get more advanced technology applied on the sheeter machine. Which we will exhibit during China Print 2021 in Beijing China.

Adhesive Paper Q&A

Can an ordinary printer print A4 self-adhesive tape?

Ordinary laser printers and inkjet printers can print A4 self-adhesive tape, but there are many precautions: 1. Print properties of traditional Chinese medicine are set to self-adhesive or thick paper mode. 2. Laser printers and inkjet printers are respectively suitable for their inkjet printing paper, but the matte adhesive tape is recommended. 3. The glue-overflowing printing paper will reduce the drum or belt of the laser printer and the inkjet printer will reduce the service life of the nozzle.

What are the differences between the dry sticker and the water sticker?

The difference between sticker dry sticker and a water sticker is that it is posted on the wall or the glass. In general, when posting post-it stickers on the wall, you can only use the “dry sticker method”, while in the glass surface construction, it is usually recommended to use the “water sticker method”.

How long can the self-adhesive paper be stored?

The best storage condition is 23 ℃ and 50% humidity. In this environment, the self-adhesive material can be stored for 1 year, after more than 1 year, it is necessary to check the stickiness and peeling degree of the paper surface material. It is recommended that plastic film sealed packaging, printed label packaging should be layered and stacked, not overweight, to prevent glue penetration and adhesion, to prevent direct sunlight.

Is self-adhesive tape harmful?

It is recommended that the plastic film be sealed and packaged. After printing, the labels should be layered and stacked, not overweight, to prevent glue penetration and adhesion, and to prevent direct sunlight.

What kind of rubbish does self-adhesive paper belong to?

Self-adhesive tape belongs to dry rubbish / other rubbish. Dry rubbish: other domestic wastes except for hazardous garbage, recyclables, and wet garbage. Common dry trash / other rubbish are jars, old bathtubs, cups, walnuts, disposable chopsticks, broken flowerpots, wooden combs, dirty clothes, basketball, toilet paper, ceramic bowls, garbage bags, tiles, brooms, etc.

How to tear the adhesive tape clean?

It’s hot. We can directly use a lighter or a hairdryer to heat the sticker to make the glue dissolve. When the label is a little hot, it’s easy to take it off.

Encounter water. If there is no lighter, we can soak these in warm water for a while and wait for the sticker to soften thoroughly. The effect is also good.

Alcohol, essential oil. Alcohol, wind oil essence and so on is also very suitable, with alcohol coated on the surface of the self-adhesive label, feel that the self-adhesive has been softened and gently torn, it can completely fall off.

What are the reasons for the raised edges of self-adhesive labels?

Glue viscosity is too weak: suitable glue material should be selected.

The pressure of the pressing wheel of the labeling machine is not enough: the reason and the solution areas above.

Label surface material: when selecting label surface material, we should consider whether the labeling object is a plane or a surface, large diameter or small diameter, a single surface or a sphere, a rigid body or a compressible deformation, these indicators are directly related to the Improper selection of adhesive: when choosing a self-adhesive adhesive, printing recommends that you first determine whether the adhesive required for the self-adhesive label is permanent or removable, whether it is pasted at one time or can be re-pasted.

Poor control of film tension: the label with the correct coating is removed from the base paper, and the label is not curled or labeled. After the label with too tight tension is removed from the base paper, the label is reversed, which leads to the phenomenon of label edge degumming and warping after labeling.

The shape design of the bottle body is unreasonable: the reasonable design should be that the surface within the labeling range of the bottle body is flat (mainly in the design of the flat round bottle body), but if the surface is partially spherical within the labeling range, the labeling area is larger when using paper labels, and the lower end of the labeling is easy to wrinkle on both sides.

This is Zoe, the above knowledge is just the tip of the iceberg, but they demonstrate how helpful the adhesive paper is. Then it could transform value chains and operations. To get adhesive paper business boom day by day.