Summer is coming. The temperature increased day by day in the whole of China.

Ice-cream become more and more popular. Even adults like it a lot.

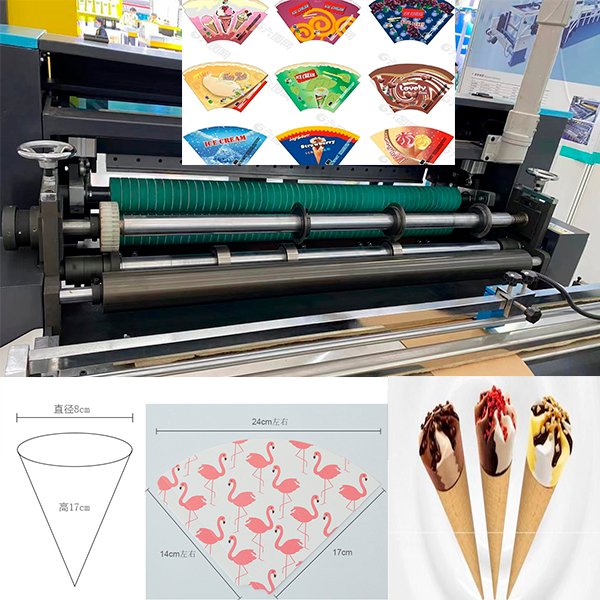

But have you ever noticed the packing material on the ice cream cone?

People will respond instinctively:” it is plastic”

It adopts paper in China.

Common Packing Material for Ice-cream

In the continuous contact with packaging users, it is found that the colleagues who are looking forward to the launch of new products also hope that their packaging can make consumers feel refreshing, to achieve the purpose of commodity promotion. The products printed with paper materials can break through the limitations of plastic bag packaging in the past. It gives full play to the advantages of good stiffness and printing adaptability of paper, and reproduces the design patterns through a variety of printing methods, to enhance the artistry of products and greatly improve the grade and added value of products.

Three Packing Material Type for Ice-cream Cone

The ice cream cone packing in China, most type is OBA-free one-side coated art paper. It is healthy. And the cost price is not high.

Then come to another compound material, foil laminated paper. Aluminum foil can reflect light and slow down radiation heat. The smooth surface of aluminum foil can form an attractive appearance with printing.

Some adopt LLDPE coated inside, and BOPP laminated outside. The raw paper is pure wood-made paper. Before the production of paper products, the inner layer of paper is first coated. That is, the inner surface of the paper is coated with a layer of LLDPE film through the coating machine at a high temperature. LLDPE is linear low-density polyethylene, food-grade, non-toxic and harmless, environmental protection material; A printing film BOPP film is compounded on the surface of paper material. BOPP film is bi-axially oriented polypropylene film, environmental protection grade, non-toxic and harmless. After changing the material structure, it will have the following advantages:

1. Greatly reduce the risk of food contamination. Because the inner wall is LLDPE film contact with food, it is no longer paper material direct contact with food. Many bacteria on the surface of the paper and the chemical composition of the paper itself are isolated, which is more in line with the requirements of health and environmental protection;

2. The food-grade LLDPE membrane can completely avoid the penetration of water and oil, which is convenient for ice cream cone manufacturers to operate, and does not need to worry about the penetration problem to ensure that the paper cone does not deform;

3. The outer layer is compounded with BOPP film after printing, which increases the glossiness of the package, makes its appearance more smooth and beautiful, and shows the high grade of the product.

But all the paper needs to reach China National Food Grade Standard.

The reason why I discuss this topic today is that of one of my Southeast Asia clients. He wants to buy an automatic sheeting machine with a color-mark length register function for his ice-cream cone packing paper roll.

Why Color-mark Register Sheeting System Is Needed?

The ice-cream paper cone has attractive pictures on it. Most of whom surface were printed.

The color-mark length register cutting function consists of a PLC program, touch screen setting, color mark tracking sensor, and its support- mechanical frame.

Working process:

1. Load the paper roll into the unwind stand.

2. Feeding the paper through all the processing rollers.

3. Positioning the color mark sensor to the print mark on the paper roll.

4. Measure the distance between every two marks and input the length into the touch screen.

5. Press the auto mark tracking icon on the touch screen.

6. Check the sensor light color. It will flash when tracking the right mark

7. Test sheeting several pieces

8. Micro-adjust on touch screen +1 or -1

9. Mass production

10. The cutting precison is ±0.2mm

It is an ideal function for those printed paper materials in a roll shape.

If next time, you got printed paper roll to do sheeting. Please do not ask the supplier to add a color-mark length register sheeting function for you.

That’s all for my sharing, see you.